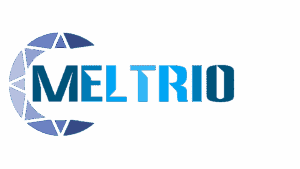

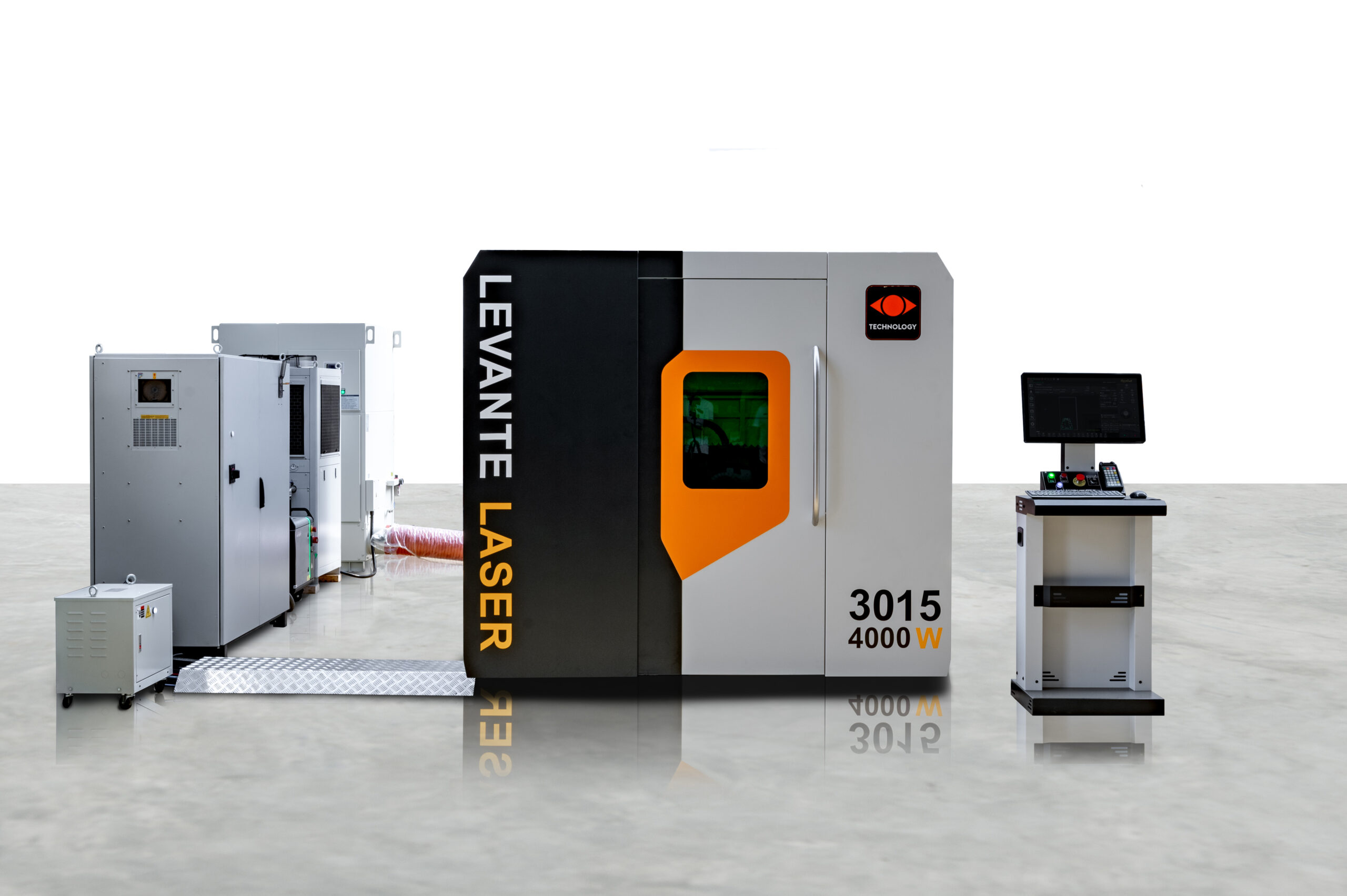

Description

WHY CHOOSE IT?

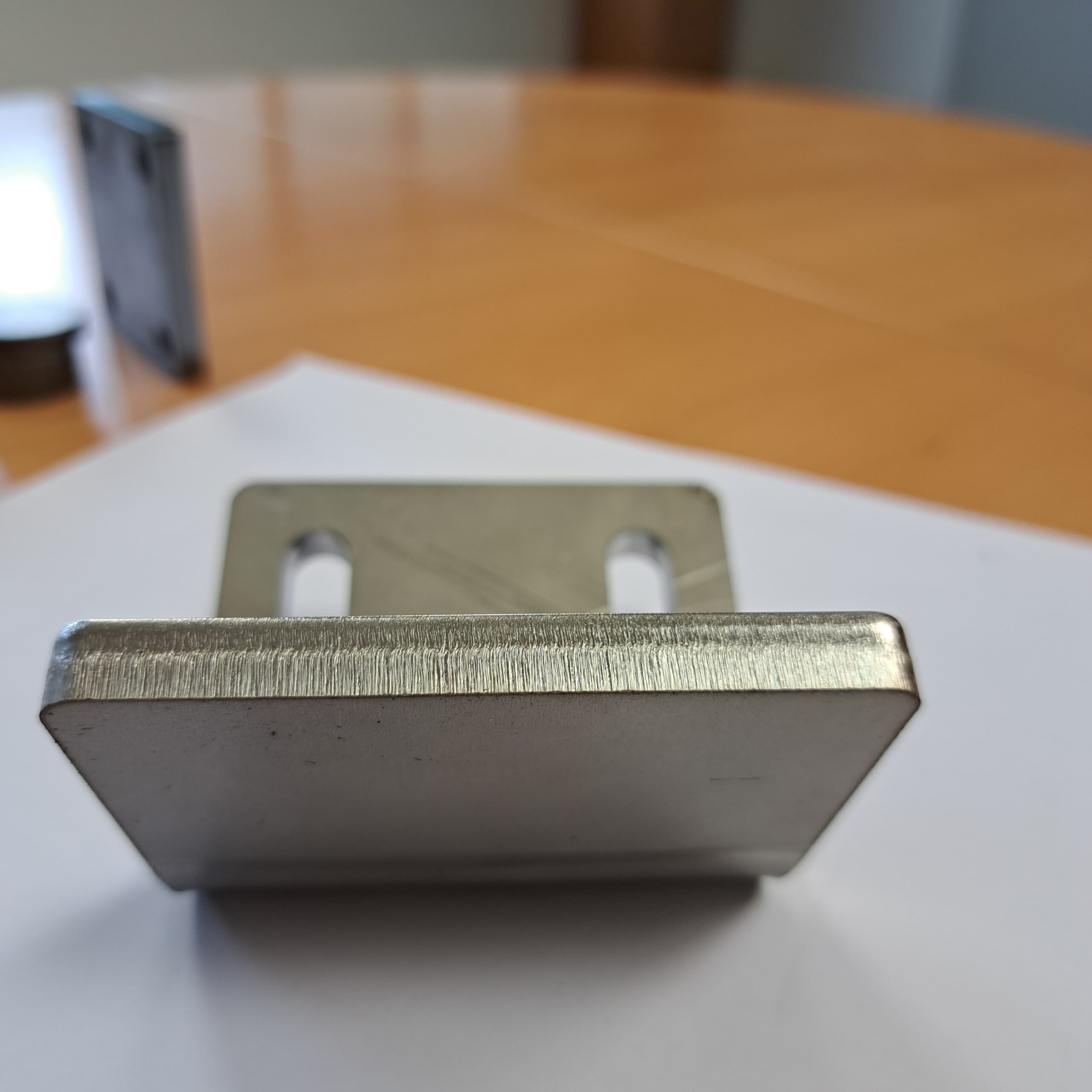

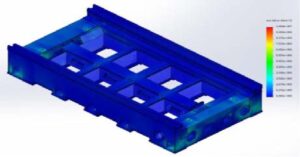

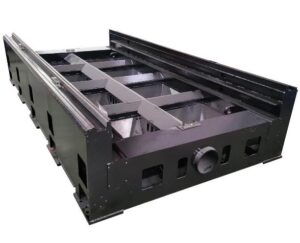

1. STRUCTURE:

• Designed with the help of 3D software and FEM structural analysis.

• Electro-welded structure subjected to stress relieving heat treatment aimed at eliminating the stresses deriving from the welds.

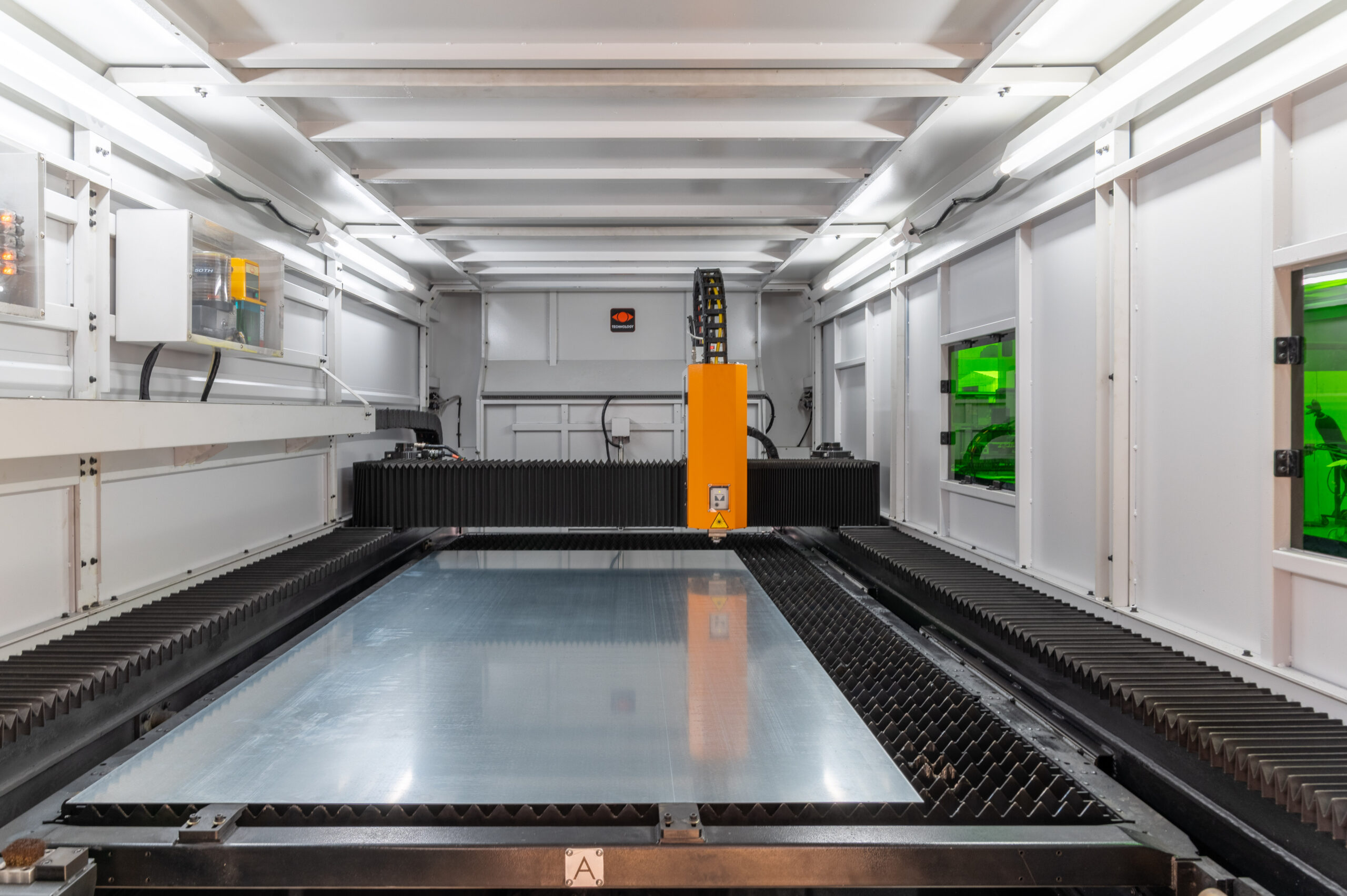

2. SUCTION BENCH:

• The suction bench is divided into sections and allows you to extract the fumes from the processes at the exact point where the head is cutting.

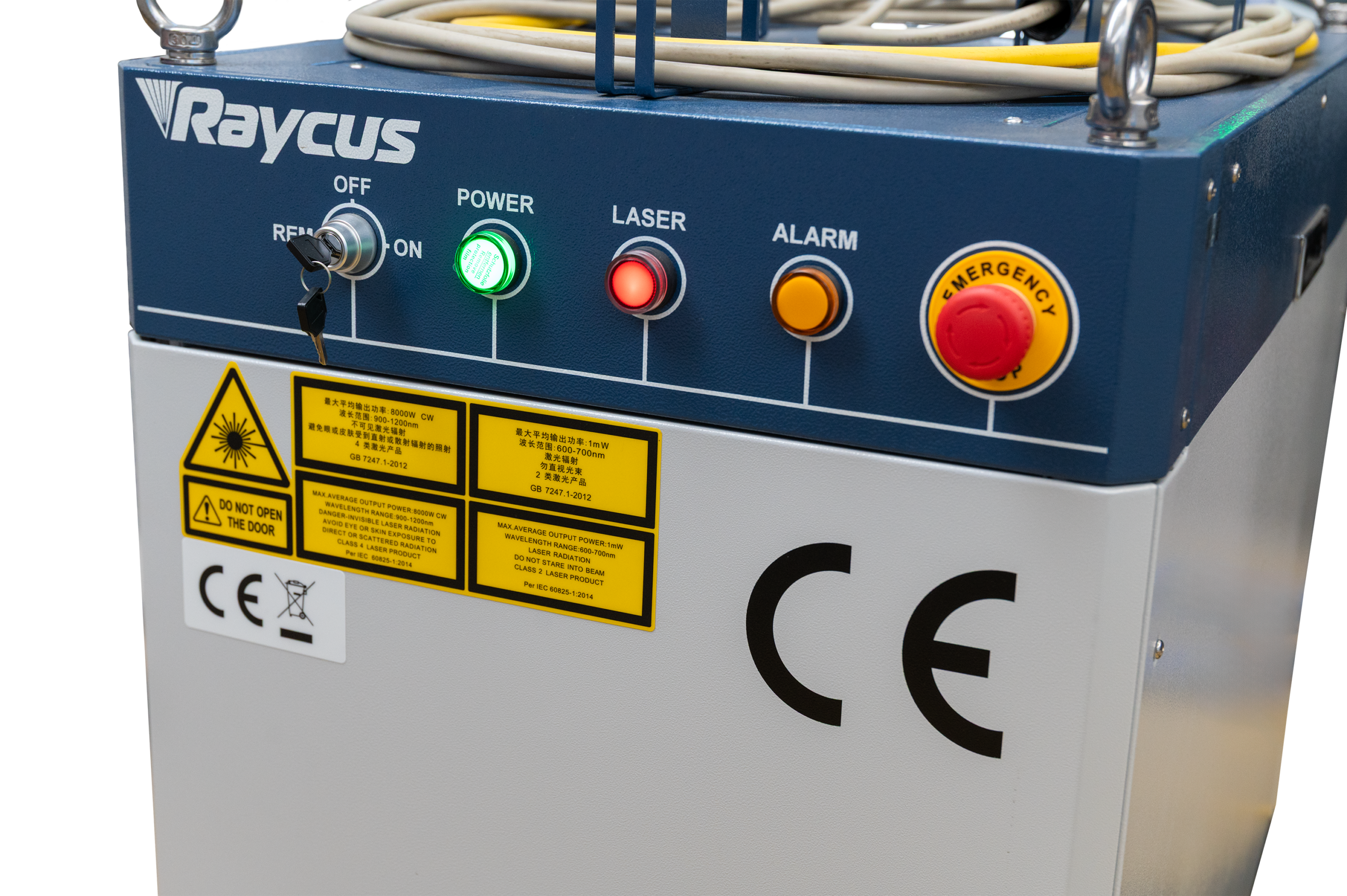

3. FIBER LASER SOURCE:

• Modular design and engineering.

• The generator is cooled through the use of a chiller system.

• Innovative anti-reflective technology that makes it easier to work with reflective materials such as: copper, silver, brass, aluminum.

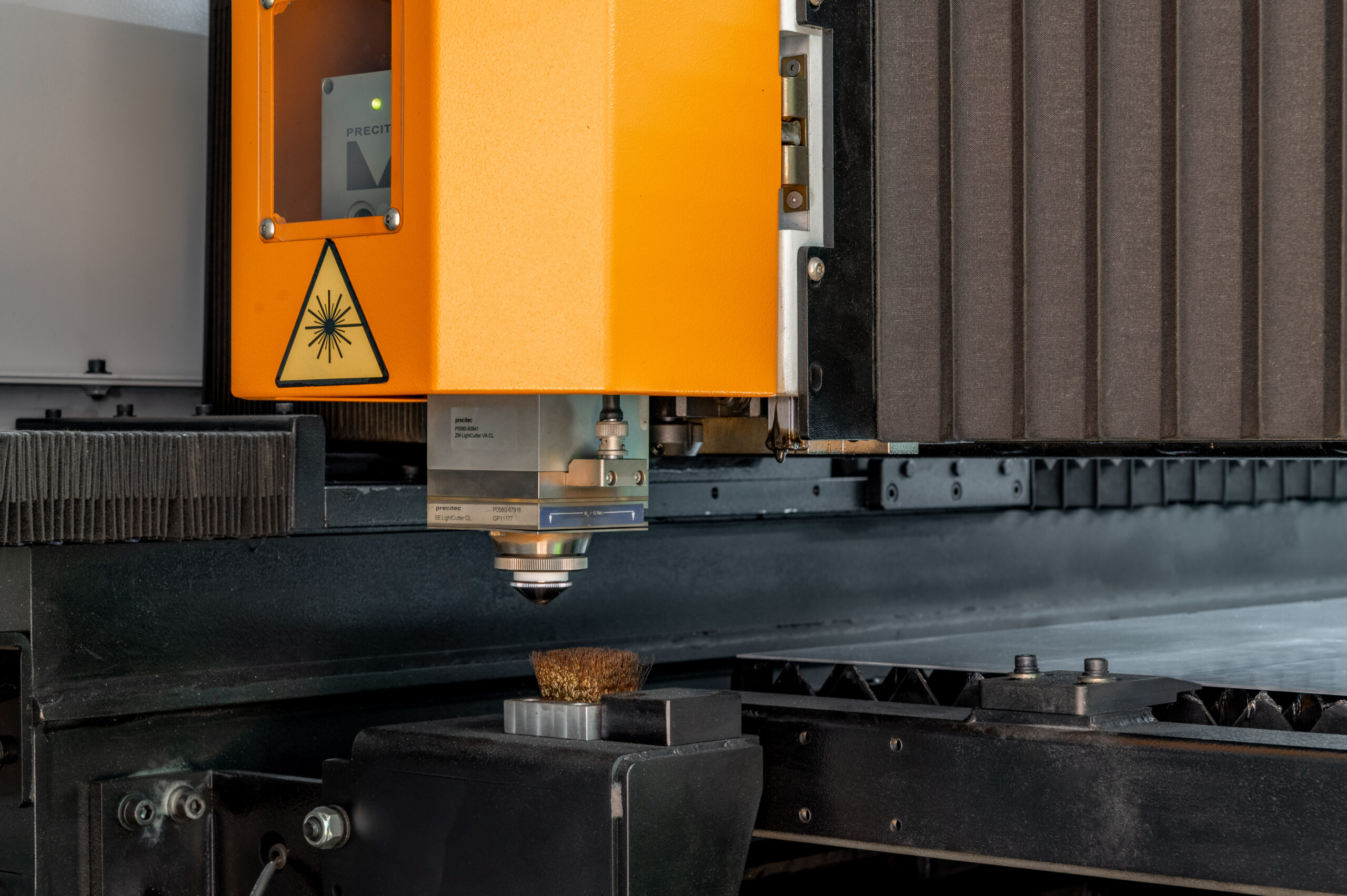

4. CUTTING HEAD:

• We have chosen is manufactured by the German company PRECITEC, a world leader in the design and production of this type of component.

• Integrated protection systems.

• The head is cooled using a chiller system.

• The head features autofocus technology.

• Automatic nozzle cleaning system.

• Automatic calibration system.

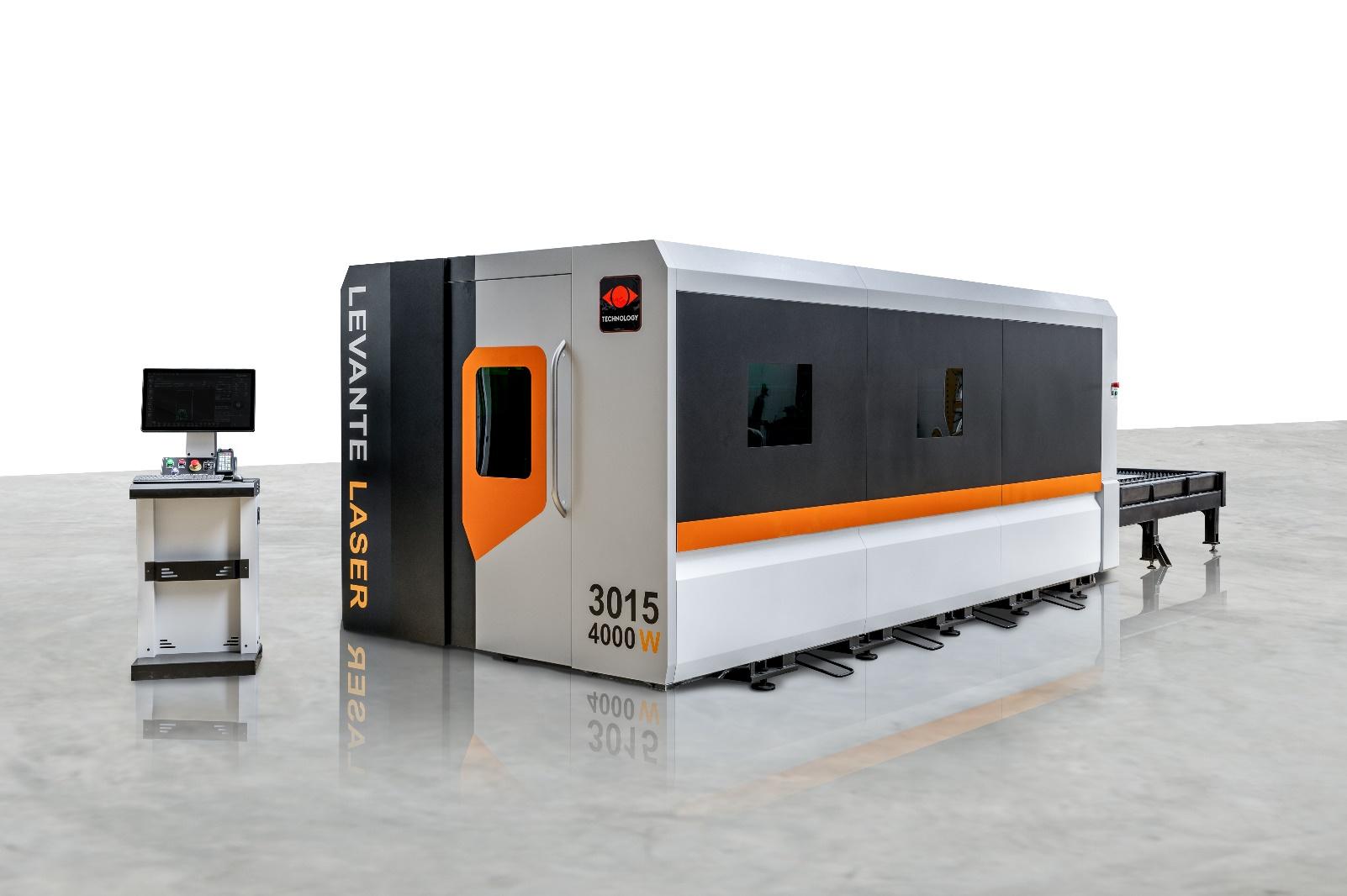

5. AUTOMATIC PALLET CHANGER:

• Solid and robust structure for loading sheet metal up to 900 kg.

• Organized on two levels

• Pallet change takes place in 14 seconds

• Equipped with brushes placed under the pallet changer trolleys to clean the sliding guides

6. CNC:

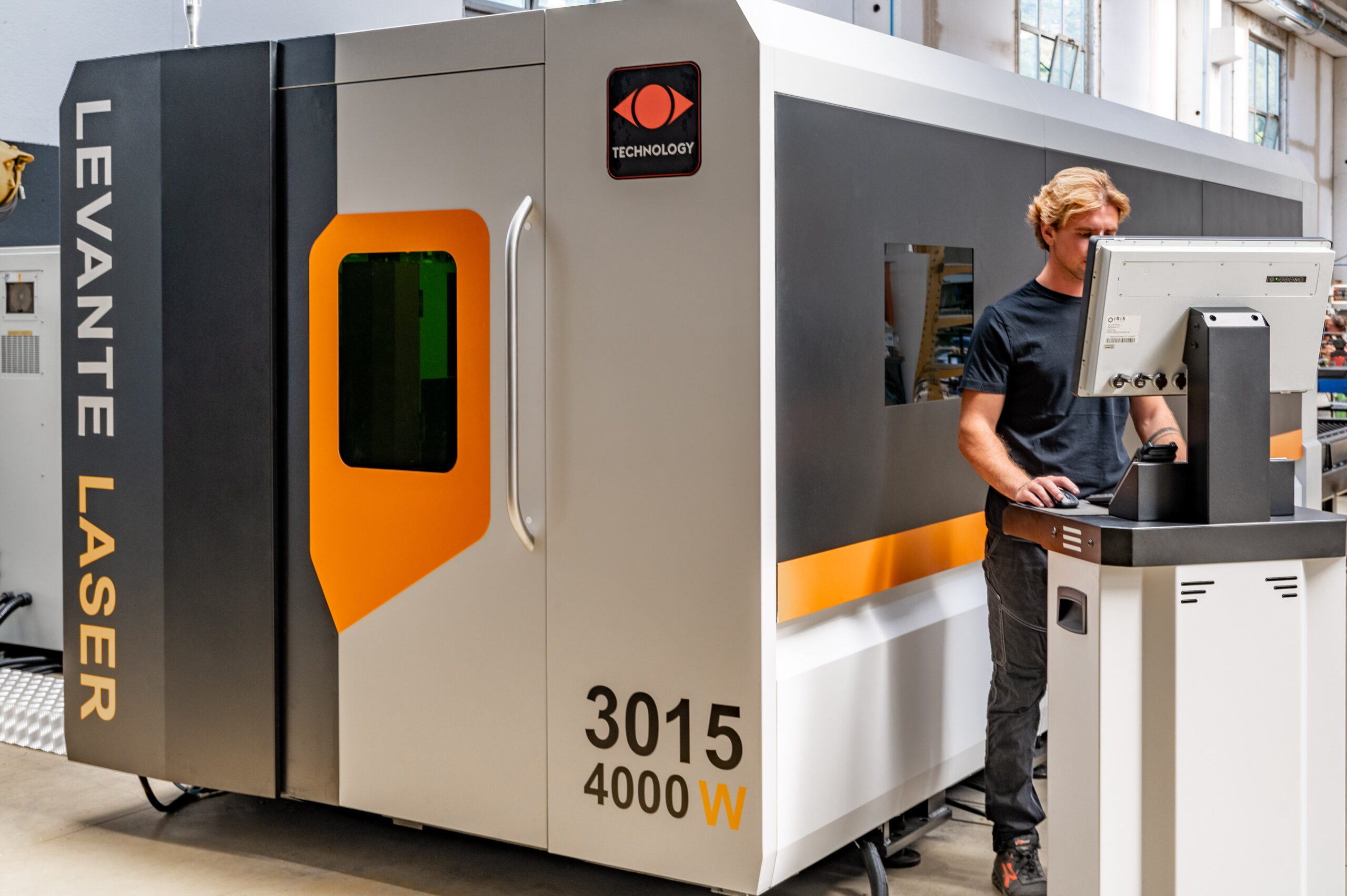

7. SIMPLE AND INTUITIVE HMI:

• The stand-alone console is separated from the machine body

• 23” Monitor

• The console is equipped with a simple and intuitive HMI interface that allows to realize fast programs on board

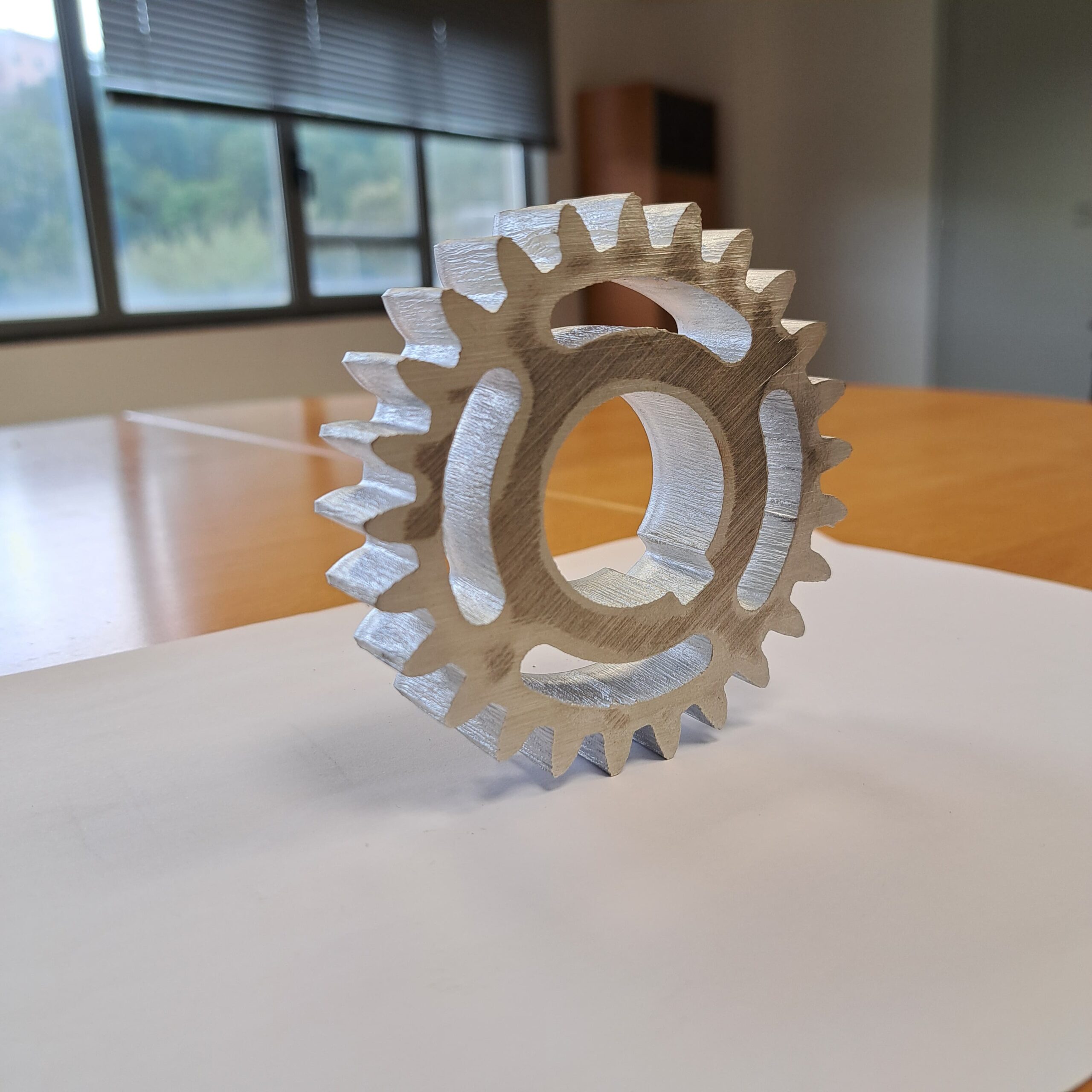

8. SELF-LUBRICATING SYSTEM:

The machine is equipped with a self-lubricating station for the guides, pinion and rack of the axes

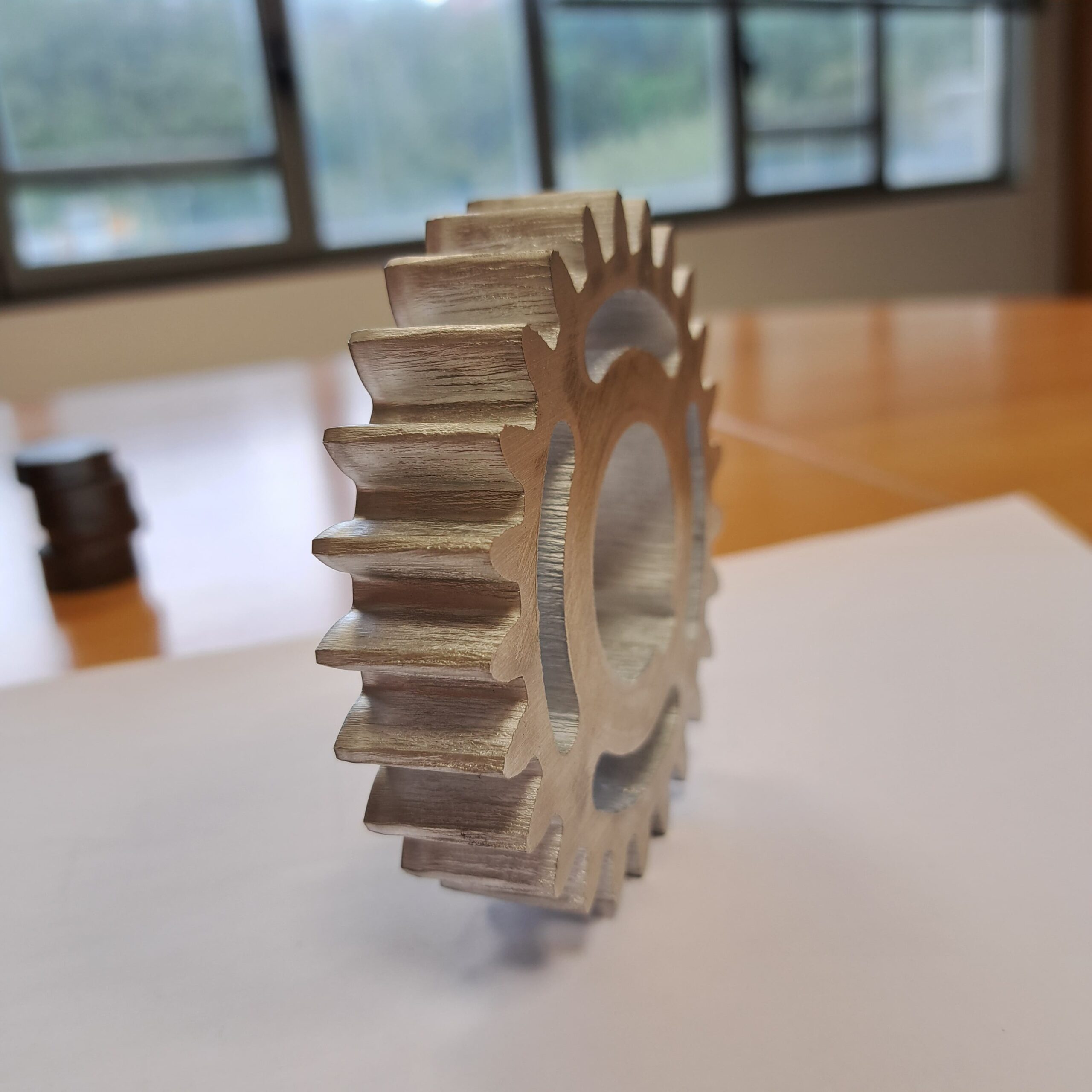

9. X and Y AXIS MOVEMENT:

• The X and Y axes are equipped with servo motors from FANUC.

• The X-axis is operated with 1 servo motor.

• The Y-axis is operated with 2 servo motors.

10. ELECTRICAL PANEL:

• Electrical panel with wiring equipped with quick coupling and release connectors

• Ventilation system with heat exchanger in the control cabinet

• The electrical cables of the system are very long, to allow different positioning during installation.

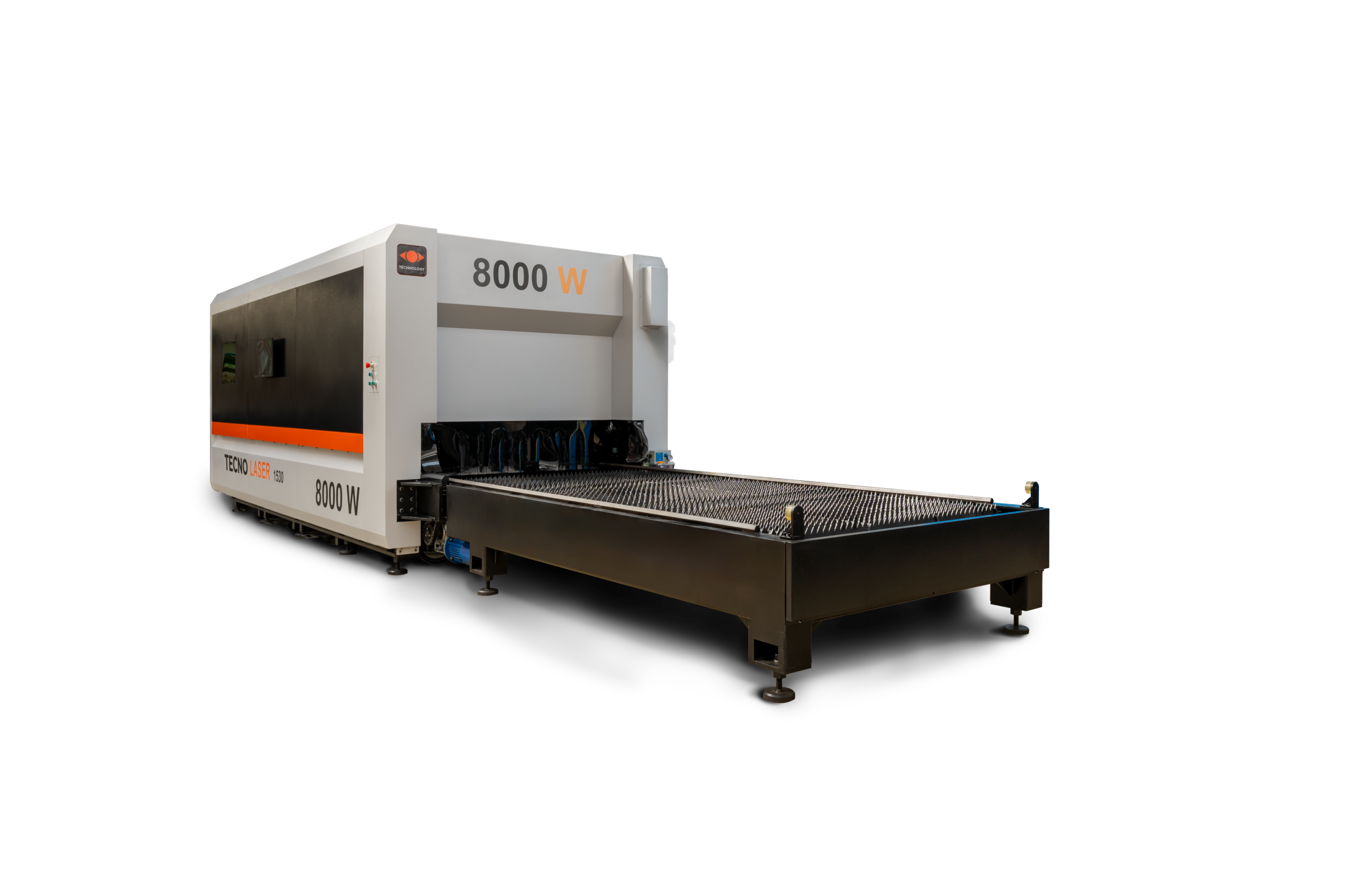

11. COOLING CHILLER:

The machine is equipped with a chiller system for cooling the laser source and the cutting head

12. RECOVERY SCARS:

The machine is equipped with 4 scrap collection drawers, divided one for each 500mm of the workbench.

13. AUTOMATIC SUCTION SYSTEM:

SIDEROS automatic fume extraction system.

Optional – Advanced automatic and programmable calcium carbonate powder dosing system. This system controls the gravimetric dosage of carbonate in the air flow coming from fiber laser cutting to work in a high-performance and safe way on aluminium alloys

14. ASSIST GAS

The machine is equipped with all the predispositions to use the 3 assistance gases:

• Air

• Oxygen

• Nitrogen

15. ASSIST GAS CONTROL SYSTEM

The machine is equipped with SMC digital pressure sensors used to monitor assist gases (Nitrogen, Oxygen, Air).

16. CAD/CAM PROGRAMMING SOFTWARE:

Our laser cutting systems can be programmed with the most common CAM and CAD/CAM office software, such as: LANTEK, JETCAM, COMPUTES, METALIX, RADAN

CUTTING TABLES

The cutting thicknesses indicated are for obtaining excellent cutting quality. Cutting of the

specified thicknesses is subject to the quality of the material and the cutting gases.

Material Auxiliary Gas Power

4000 W 6000 W 8000 W

Iron Oxygen 22 mm 25 mm 30mm

Stainless steel Nitrogen 12 mm 20 mm 25mm

Aluminium Nitrogen 10 mm 16 mm 30mm

Brass Nitrogen 8 mm 12 mm 14mm

Copper Oxygen 4 mm 6 mm 10mm